Supply chain shortages slow deliveries and production

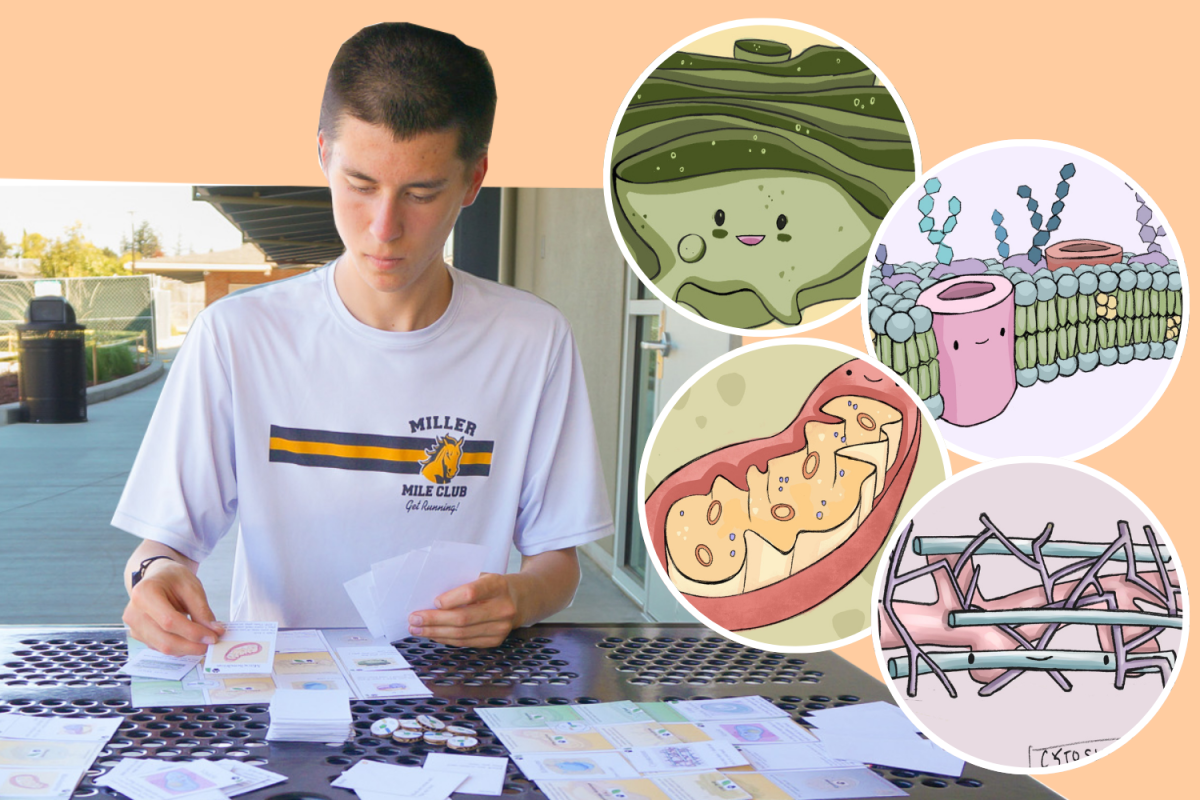

Graphic illustration by Ria Phelan

Most U.S. imports arrive from overseas in containers, and the lack of cargo space has rendered imported goods too expensive for some local retailers.

December 7, 2021

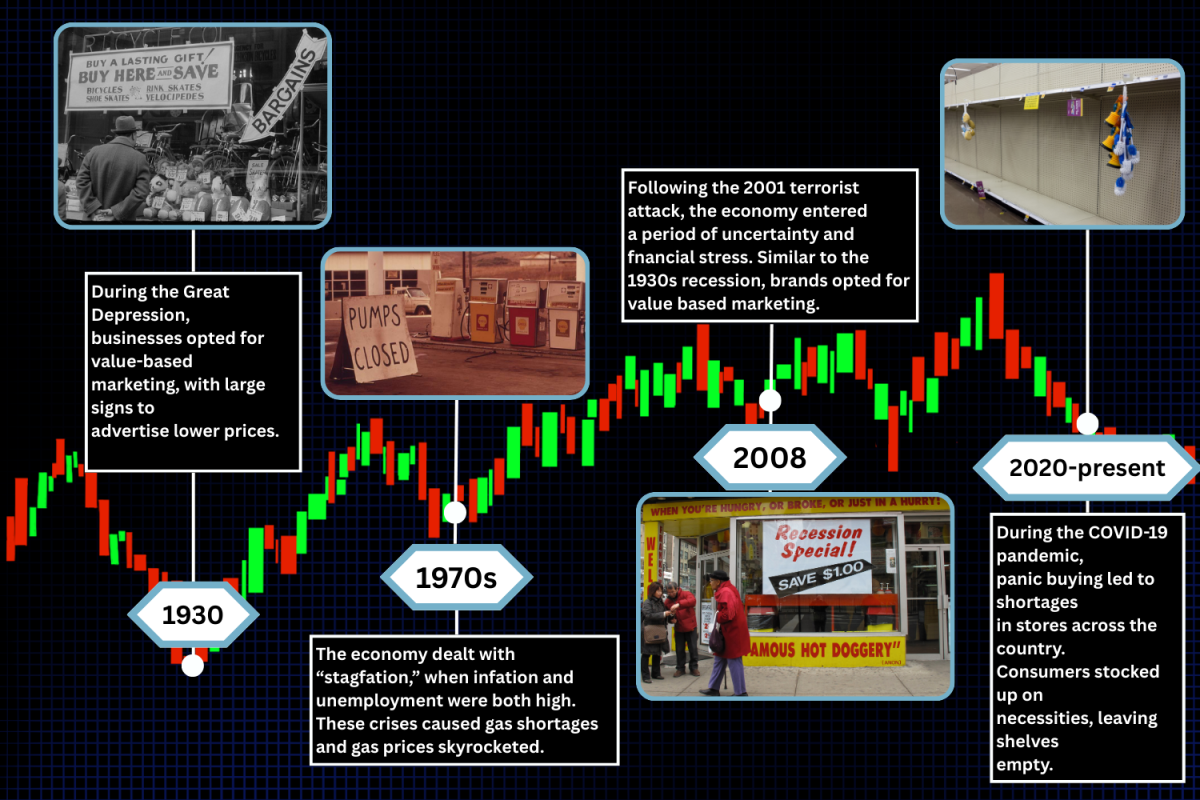

Supply chain shortages and increasing inflation from the COVID-19 pandemic have hindered the exportation of different items, ranging from fruit syrups to computer chips, to the Bay Area and across the world.

Since the beginning of the pandemic, supply chains across the globe have suffered major disruptions due to nationwide lockdowns and restrictions imposed on factories and production facilities. Although millions of white-collar workers have been able to work from home, many factories and their blue-collar workers have not been able to do the same.

Factories require many workers, but employees often are unable to follow COVID-19 safety precautions because the nature of their employment involves operating equipment in close proximity to others. With many taking leave for personal issues, the exportation of raw materials and finished products has been hindered, leading to delays in production. In addition, many workers are also quitting their jobs, citing dangerous and unfair conditions at work, low wages and overwork. And although worker shortages have always been prevalent in factories, the devastating effects of COVID-19 have resulted in as many as 1.4 million open positions.

The drastic reduction of supply has affected the purchase of everyday items, both in-person and online, as businesses and shoppers experience delays in shipping due to a lack of movement in docks and storage facilities.

For instance, the Long Beach-Los Angeles port complex, which receives 40% of all shipments from Asian factories nationwide, has been obstructed with thousands of containers loaded onto ships waiting in docks. Receivers and workers shortage is worse than ever before, causing substantial delays as customers splurged during the holiday season.

“Recently, I bought a couple of sweatshirts online that didn’t arrive until three weeks after the initial estimated delivery date,” junior Kevin Davies said. “My guess is that there are a lot of delays because we’re coming close to the holiday season, and everyone is buying presents online. Most manufacturers are in different countries with different COVID-19 regulations, which probably causes delays in shipping products from there to here.”

Production of new vehicles and cars has also been halted due to a shortage of microchips, a necessary component of vehicle navigation systems. Caused by the pandemic’s closure of computer chip factories, this shortage has started March 2020 and has persisted ever since. When paired with the sharp increase in demand for technology since the start of the pandemic, it has caused significant problems for car dealers.

“There are no more car sales events or promotions in the U.S. these days, and you can’t see a car or test drive in-person — you have to sign a contract only by looking at pictures,” said Hongjoon Yoon, employee of multinational semiconductor contract manufacturing and design company GlobalFoundries. “Vehicles require a lot of semiconductor chips as building components, but the quantity that can be produced cannot keep up with demand due to a lack of semiconductors. In the early days of the pandemic, there was a shortage of production manpower itself, and over time, it affected the supply chain, so there are double hardships.”

Supply chain problems have also resulted in inflation of food, vehicle, gas and shelter prices. According to the U.S. Bureau of Labor Statistics, prices in 2021 increased by 6.2%, a percentage that had not been reached since 1982, with October 2021 alone tallying a hefty 0.9% price increase.

Furthermore, several shipping companies have raised prices because of limited cargo space on ships. Most U.S. imports arrive from overseas in containers, and the lack of cargo space has rendered imported goods too expensive for some local retailers. Many local businesses have had to find new solutions to address product shortages they wanted. For example, Go Fish Poke Bar stopped serving yellowtail and replaced it with a new item called the seared salmon mix.

“We used to provide yellowtail, but now it’s a little bit more expensive, so our company does not want to buy it anymore,” Go Fish Poke Bar back of house employee Ryan Ehara said. “This has definitely affected us negatively.”

Another nearby boba business, Mr. Sun Tea, has also been affected due to cargo space limits and the pandemic. Ingredients are scarce because of the shipping constraints since the ingredients come from Taiwan, Vietnam and China, regions majorly affected by COVID-19.

“We make handmade boba so we get the powder from Taiwan, which gives us an advantage,” Mr. Sun Tea business partner Justin Chen said. “Most people get pre-manufactured boba, and they’re all fighting for that. Luckily, we just get the ingredients, and then we can make boba here in the United States.”

Supply chain and inflation issues resultant of the pandemic can potentially have dramatic effects on the business industry and economy if left unchecked. Thus, many businesses are starting to explore different work environments and large changes in standard processes to combat these issues.